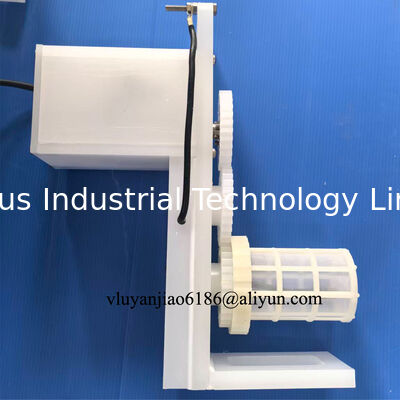

Mini PP Electroplating Barrel With Single Basket 60100mm For Small Electroplating Tank

Mini Plating Barrel Assembly 60*100mm

Mini barrels and baskets that are versatile and efficient. Great for plating, tumbling, cleaning, and polishing of loads that are small and delicate.

Mini Barrels and 6" Baskets are ideal for processing small or delicate work such as medical, electrical or electronic parts, precious metals and jewelry. Small barrels and baskets are also used often in the laboratory for product or process development.

Various superstructure mounting, and barrel configurations are available.

Integral Mini Barrel Mesh Construction:

Both the Mini Barrels and the 6" Plating Baskets are uniquely injection-molded, constructed with polypropylene and integral meshing.

* The fine mesh allows the processing of tiny components, even those with delicate wire leads.

* Permits excellent electrolyte exchange, fast draining and rinsing.

Free Standing Assembly:

Small Baskets are typically furnished as standalone assemblies for convenient use with simple tanks and other equipment. Other mountings, such as multiple barrels or hanging supports from cathode contacts are available.

| Rank |

Item |

Electroplating Equipment |

| 1 |

Material of tank |

PP(Polypropylenep) /PVC Plate (Polyvinyl chloride) and Customized |

| 2 |

Material of framework |

Galvanized Steel With Epoxy paint |

| 3 |

Model |

manually type |

| 4 |

Control system |

Manually |

| 5 |

Heating |

Stainless Steel Heating Tube/Quartz Heating Tube/Titanium Heating Tube |

| 6 |

Surrounding equipments |

Rectifiers, Filters, Water Chiller ,Pipe, Air blower, waste gas treatment system and so on |

| 7 |

Application |

Different kind of plating for metal ,Steel and plastic products |

More Products:

Manual barrel plating production line can be plating for zinc,copper,gold,nickel etcelectroplating anode oxidation.

It has characteristics of small volume,easy operation,low covering area and low price,and it also has provided some

electronics factory and some plating needed company with great convenience.

Characteristics:

●Made in polypropylene and corrosion resistence to high temperature;

●Simple and convenient manual operation and excellent performance;

●Suitable for small batch production of small workpieces and hanging up and down materials;

●Small covering area and low price;

●This kind of production is fit for hardware and electronic etc industry and it can be controlled its process flexibly;

●Driven by motor and worm gear speed reducer,the speed is 6-30R/min(Adjustable speed).

SPECIFICATION OF ELECTROPLATING EQUIPMENT:

1. High quality raw material : 10--15mm PP / PVC plate (Welcome customized )

2. Anti-corrosion and resistant machinery frame and Crane lifting : Steel body and Epoxy painting.

3. Main equipment model :

(1) According to plating method : Barrel plating and Hang plating

(2) According to Control system : Portable equipment ; Manual plating line ; Semi-automatic plating line ; Full-automatic line .

(3) According to application : Zinc plating ; Nickel plating ; Chrome plating ; Copper plating ; Gold plating ; Anodizing and etc.

4. Welcome customized : the electroplating line is non-standard , it is designed according to your products information .

5. Testing before delivery :

(1) Anti-leakage testing : We will fill the tanks with water after welding and before installation , the testing time last 72 hours .

(2) Runing testing : We will installed the equipment and operate it . Meantime , we will take the testing videos to the customer to confirm it .

6. Guarantee : one year ( We will replace the external equipment for free except the human damaged )

7. We are factory .We have the best price .

8. We have Export license , we can export to your area directly .

9. Surrounding equipments :

| Pre-treatment equipment |

Ultrasonic degreasing equipment , Washing machine , Vibrating polishing machine |

| After-treatment equipment |

Oven , Dryer |

| External equipment |

Rectifier , Filter , Chiller |

| Water cycle system |

Input and output plastic pipes and value |

| Exhaust system |

Air cover, ventilation pipe, Exhaust fan , Acid mist tower, Air box |

Packing & Shipping

In our company,various packing methods are adopted according to different product features,such as carton boxes,wooden case etc.For electroplating plant equipment ,we can discuss it together and choose the most suitable one.

As for shipment,different ways have their own advantage and disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, expensive

By Express: more flexiable, door to door, expensive

Company Advantage:

1. Professional,Powerful, Precision Design

- Factory scale: 18 years of experience in electroplating equipment manufacturing, with a production base of 5182 square meters, factory direct sales, reducing customer costs.

- Processing equipment: 20 sets of bending machines, engraving machines, wire cutting machines, processing machine tools and other machinery to ensure the quality of customized equipment.

- Customized production capacity: The annual production capacity of electroplating equipment can reach 24 sets, and the customized equipment can be supplied in a timely manner with strong strength.

2. Build a quality levee to meet the challenges of the century

- Exquisite craftsmanship: simple and flexible operation, stable operation, easy to manage, low mechanical failure rate, high use efficiency

- Superior quality: The equipment adopts materials from well-known brands in Japan, Taiwan and China to ensure stable and durable equipment quality

- Strict quality inspection: repeated testing of equipment after on-site installation to ensure equipment stability and equipment quality

3. Focus on research and development for 18 years, master core technology

- R&D team: Engineers have more than 18 years of experience in the electroplating industry, and continuously improve the quality of equipment to provide technical assurance

- R&D strength: By increasing investment in science and technology, improving the level of R&D, now we have advanced technology R&D and design capabilities in the industry

4. Quality and Thoughtful Service

- The engineer answers online, and the salesman's response time does not exceed 4 hours.

- Quick quote

Related Product Show

1. Automatic Barrel plating production line

2. Automatic rack plating production line

Application: large-scale surface treatment of metal parts such as machinery, automobiles, military industry,electronics and ABS

non-metal parts, suitable for zinc plating, chrome plating, nickel plating, copper plating and other processes.

3. Precision roller

Application range:Small batch surface treatment of metal parts such as precision military electronics, suitable for nickel plating,

gold plating, tin plating, copper plating and other processes

Related Project display

Others Applications

Ultra-High-Purity Heating

Designed with Ultra-High-Purity processes in mind, Surplus delivers clean-room assembled, reliable heating and power solutions to fit specific needs.

Products For Ultra-High-Purity Heating

|

|

Inline Heater

|

PFA Inline Heater

|

Inline Chemical Heater

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!