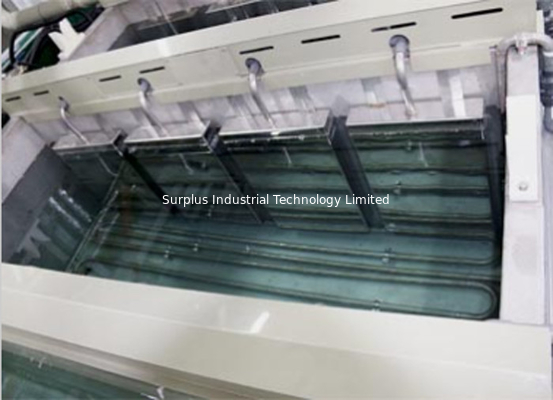

SUS304 Ultrasonic Cleaning Tanks For Cleaning And Degreasing Of Electroplating Equipment

Characteristic

- Used for cleaning and degreasing of electroplating production line and oxidation production line

- The tank body is made of SUS304 board, according to customer requirements

- The tank vibration plate is made of SUS304 material

Electroplating Tanks Induction

PP anti-corrosion acid resistant laboratory plating bath is most commonly used in electroplating equipment and tank pickling tank. The material is the use of PP material and steel material. The plating bath can be used to do the device for the dissolution of zinc, copper, nickel, gold and so on. The mobile cathode plating bath by the steel tank lining soft PVC tank, conductive device, steam heating pipe and composition the mobile cathode device.

Electroplating Tanks Features:

Electroplating baths are the most common sink and pickling tank in electroplating equipment. The material is made of PP material and steel structure material. Electroplating tanks can be used to install solutions for galvanizing, copper plating, nickel plating, gold plating and the like. The cathode moving plating tank is composed of tank body, conductive device, steam heating tube and cathode moving device of steel groove lining soft PVC plastic. The choice of the tank structure depends on the nature of the bath and the temperature and other factors. It consists of tank body, solution heating and cooling device, conductive device, motor, reducer, eccentric disk, connecting rod and pole support roller.

The optimum size of the plating bath is of great importance to the growth plan, the estimation of the yield and the quality of the plating.

To determine the size of the plating tank need to meet the three conditions:

- To meet the processing requirements of the parts, to fully submerged parts to be electroplated all the surface;

- To maintain the plating cycle of electrolyte content of certain stability;

- But also take into account the overall coordination of the production line to meet the rationality of electroplating workshop layout requirements.

Electroplating Tanks Technology:

1. The cathode moving electroplating tank is composed of a steel tank lined with soft polyvinyl chloride plastic tank body, conductive device, steam heating tube and cathode moving device.

2. The tank can also be made of steel frame lined with hard polyvinylchloride plastic. The choice of tank structure depends on factors such as the nature and temperature of the electroplating bath. It consists of a motor, a reducer, an eccentric disc, a connecting rod and a pole supporting roller.

3. The main components of the tank include tank body, solution heating and cooling device, conductive device and stirring device, etc. Sometimes the tank directly contains the solution such as a hot water tank, Sometimes the basic requirement of the lining matrix or framework such as steel channel is that it does not leak and has a certain degree of rigidity and strength, so as to avoid damage to the lining layer due to excessive tank deformation;The bottom surface of the steel tank should be 10mm~12mm away from the ground to prevent serious corrosion.

Packing & Shipping

In our company,various packing methods are adopted according to different product features,such as carton boxes,wooden case etc.For electroplating plant equipment ,we can discuss it together and choose the most suitable one.

As for shipment,different ways have their own advantage and disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, expensive

By Express: more flexiable, door to door, expensive

FAQ

- How can I get an offer?

You can send your drawing with technology requirements and mark your purchase quantity of the product you need.It is much better if you could offer the usage information about products.

We will comfirm the most suitable material and quote our best price to you in 24 hours.

- Can you accept OEM & ODM?

Yes,we can produce the products according to your demand and drawing.

- What is your production lead-time for order?

Generally it takes 15-25 days for production.

- What are your payment terms?

In generally,we quote EXW price+shipping cost,payment 50% deposit by T/T in advance,50% balance paid before shipment.

If the account is small ,so you can pay via Western Union.

Company Advantage:

1. Professional,Powerful, Precision Design

- Factory scale: 18 years of experience in electroplating equipment manufacturing, with a production base of 5182 square meters, factory direct sales, reducing customer costs.

- Processing equipment: 20 sets of bending machines, engraving machines, wire cutting machines, processing machine tools and other machinery to ensure the quality of customized equipment.

- Customized production capacity: The annual production capacity of electroplating equipment can reach 24 sets, and the customized equipment can be supplied in a timely manner with strong strength.

2. Build a quality levee to meet the challenges of the century

- Exquisite craftsmanship: simple and flexible operation, stable operation, easy to manage, low mechanical failure rate, high use efficiency

- Superior quality: The equipment adopts materials from well-known brands in Japan, Taiwan and China to ensure stable and durable equipment quality

- Strict quality inspection: repeated testing of equipment after on-site installation to ensure equipment stability and equipment quality

3. Focus on research and development for 18 years, master core technology

- R&D team: Engineers have more than 18 years of experience in the electroplating industry, and continuously improve the quality of equipment to provide technical assurance

- R&D strength: By increasing investment in science and technology, improving the level of R&D, now we have advanced technology R&D and design capabilities in the industry

4. Quality and Thoughtful Service

- The engineer answers online, and the salesman's response time does not exceed 4 hours.

- Quick quote

Related Product Show

1. Automatic Barrel plating production line

2. Automatic rack plating production line

Application: large-scale surface treatment of metal parts such as machinery, automobiles, military industry,electronics and ABS

non-metal parts, suitable for zinc plating, chrome plating, nickel plating, copper plating and other processes.

3. Precision roller

Application range:Small batch surface treatment of metal parts such as precision military electronics, suitable for nickel plating,

gold plating, tin plating, copper plating and other processes

Related Project display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!