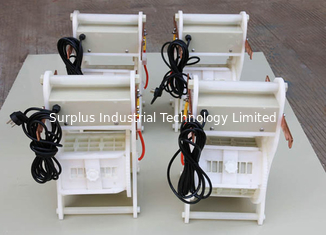

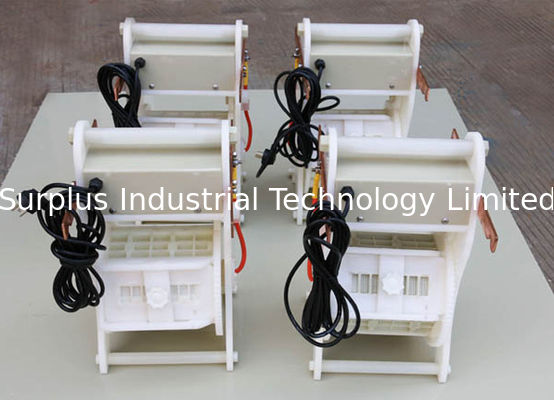

PP Electroplating Line Precision Barrel Plating Machine for Gold Nickel Zinc Plating

PP Electroplating Line Precision Barrel Plating Machine is suitable for surface treatment of metal products. It is usually to be done nickel plating, galvanization, gold plating, silver plating, and copper plating on the surface of products. It is widely used in the production of screws, nuts, nuts, faucets, etc.

Electroplating is the process of electroplating a thin layer of other metal or alloy on the surface,of certain metals by electrolysis. It is a process of using electrolysis to attach a metal film to the surface of metal or other materials to prevent metal oxidation ( Such as rust), improve the wear resistance, electrical conductivity, reflective, anti-corrosion (copper sulfate, etc.) and enhance the appearance and other effects. The outer layer of many coins is also electroplated.

Parameters Table

| Item Name |

PP Electroplating Line Precision Barrel Plating Machine for Gold Nickel Zinc Plating |

| Material |

PP Board |

| Application |

Suitable for barrel plating of gold, silver, palladium, rhodium, nickel, copper, zinc |

| Speed |

Automatic Speed Regulation,Can design positive and negative system |

| Included Fitting |

Speed Motor |

Packing & Shipping

In our company,various packing methods are adopted according to different product features,such as carton boxes,wooden case etc.For electroplating plant equipment ,we can discuss it together and choose the most suitable one.

As for shipment,different ways have their own advantage and disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, expensive

By Express: more flexiable, door to door, expensive

FAQ

1. Q: We need plating machine for ×××, could you send me a quotation?

A: Because plating machine is always customized for different products, we'd like to send you quotation and make the design for you based on knowing detailed information from you first.

2. Q: What is the necessary information you need for design?

A: The plating prosess you have had, The capacity of your per products, The material, weight, size, and surface area of your per product, The thickness of plating layer, Your working hours per day, Type of salt spray test and time, Workshop dimension and so on

3. Q: What's the lead time for one project?

A: It usually would take about 15-30days for production and the time is based on specific projects.

4. Q: How can I carry out my work if I plan to set up a new plating line?

A:It would be better if we could communicate with your chemical liquid supplier on the process details first. Besides, professional engineer is also important for your project.

Company Advantage:

1. Professional,Powerful, Precision Design

- Factory scale: 18 years of experience in electroplating equipment manufacturing, with a production base of 5182 square meters, factory direct sales, reducing customer costs.

- Processing equipment: 20 sets of bending machines, engraving machines, wire cutting machines, processing machine tools and other machinery to ensure the quality of customized equipment.

- Customized production capacity: The annual production capacity of electroplating equipment can reach 24 sets, and the customized equipment can be supplied in a timely manner with strong strength.

2. Build a quality levee to meet the challenges of the century

- Exquisite craftsmanship: simple and flexible operation, stable operation, easy to manage, low mechanical failure rate, high use efficiency

- Superior quality: The equipment adopts materials from well-known brands in Japan, Taiwan and China to ensure stable and durable equipment quality

- Strict quality inspection: repeated testing of equipment after on-site installation to ensure equipment stability and equipment quality

3. Focus on research and development for 18 years, master core technology

- R&D team: Engineers have more than 18 years of experience in the electroplating industry, and continuously improve the quality of equipment to provide technical assurance

- R&D strength: By increasing investment in science and technology, improving the level of R&D, now we have advanced technology R&D and design capabilities in the industry

4. Quality and Thoughtful Service

- The engineer answers online, and the salesman's response time does not exceed 4 hours.

- Quick quote

Related Product Show

1. Automatic Barrel plating production line

2. Automatic rack plating production line

Application: large-scale surface treatment of metal parts such as machinery, automobiles, military industry,electronics and ABS

non-metal parts, suitable for zinc plating, chrome plating, nickel plating, copper plating and other processes.

3. Precision roller

Application range:Small batch surface treatment of metal parts such as precision military electronics, suitable for nickel plating,

gold plating, tin plating, copper plating and other processes

Related Project display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!