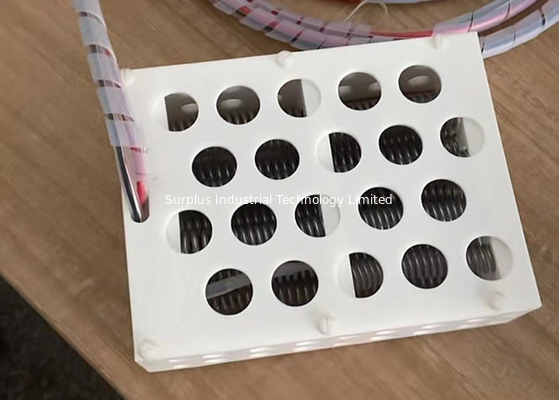

Customized PTFE Fluoroethylene Frame Tank Heater Immersion Heaters Heat Different Liquid Solution

Overview

Customized PTFE Fluoroethylene Frame immersion tank heaters are great for heating fluid baths to a constant temperature.

These heaters are ideal for use in the semiconductor, pharmaceutical, and biomedical industries.

First of all, these immersion heaters provide clean heat evenly and efficiently.

Furthermore, they’re compact and highly customizable. They provide a maximum process work area, and consume a minimal amount of chemicals.

Moreover, wetted surfaces feature all-PFA materials, and may be used in tanks made of PVDF, PFA, or quartz.

Please contact us with inquiries about other tank materials

Electric immersion heaters provide flexible design options that allow you to effectively heat most any metal finishing solution.

Design Options – Over the side, L-Shaped, Coiled, Pancake, Triple-Tube

Materials – Carbon Steel, Stainless Steel (304, 316), Fluoropolymer (PTFE), Quartz and Titanium

Available in 120, 240 Single or Three Phase or 480 Volts

Watt densities ranging from 1000 to 36,000 Watts

To properly size an electric immersion heater, we need to know the following:

- Type of chemistry being heated (application and concentration)

- Tank dimensions and solution height (L” x W” x H”)

- Incoming voltage (110V, 240V Single or Three Phase, 480V)

- Heat Up Time (how long will it take for the solution to get to operating temperature)

- Operating Temperature

- Ventilation requirements

How To Select A Chemical Solution Heater

For corrosive solutions heating, the best of heater will depend on:

- pH value- either highly acidic or alkaline

- Specific heat and density of the chemical solution

- Sheath and plating tank material

- Corrosion resistive property of the materials

Dont hesitate to contact us, we have been helping manufacturers heat dangerous chemicals for almost 50 years. Custom designed L shaped or bottom immersion heaters made of Teflon are also available.

FAQ

Q: What are the Applications of an Immersion Heater?

A: Each type of immersion heater is suited for different types of applications. Water, oils, solvent, plating baths, salts, and acids are some of the many liquids and viscous materials commonly heated with immersion heaters.

Below are the most common applications for the different types of immersion heaters:

Over-the-side immersion heaters are best for applications where ample working area and portability, such as for easy removal for cleaning of tanks and heaters, is important.

Flanged immersion heaters are excellent heater choice for all tanks, vats, or irregularly shaped vessels due to the wide selection of watt densities, heating outputs, and flange sizes and ratings of these heaters.

Screw plug immersion heaters are ideal for process water heating and freeze protection. All types of oils and heat transfer solutions can also be heated using these compact and easily controlled units. The direct immersion method is energy efficient and well suited for many applications.

Q: Where is Surplus located?

A: Our office located in HongKong,Dongguan and Shantou City.Our factory located in Shenzhen.

Q: Can I buy direct?

A: Yes,you can buy from Surplus Directly.

Q: Do you manufacture your products in house?

A: Most of our products are manufactured in-house at our factory.Some accessory items are not.

Q: Can I get the riser on my L-shaped aquaculture heater longer/shorter?

A: Yes.There is no price difference for making a heater with a middle riser,but there maybe a cost adder for a longer riser.

Q: What Third Party Approvals do your products carry(CE?)

A: Almost all of our products are CE compliant.

Q: How late can you ship?

A: Normally 7 days after comfirmed the order.

PACKING & SHIPPING

In our company,various packing methods are adopted according to different product features,such as carton boxes,wooden case etc.For electroplating plant equipment ,we can discuss it together and choose the most suitable one.

As for shipment,different ways have their own advantage and disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, expensive

By Express: more flexiable, door to door, expensive

RELATED SPECIES

|

|

|

| METAL IMMERSION HEATER |

PTC IMMERSION HEATER |

QUARTZ IMMERSION HEATER |

|

|

|

| METAL HEAT EXCHANGERS |

(PFA) HEAT EXCHANGERS |

ANODE BASKET |

|

|

|

| PP TANKS |

PP BARRELS |

PP BAG FILTERS |

OUR FACTORY

|

|

|

| ENGINEER OFFICE |

TOOLING DEPARTMENT |

MACHING 1 |

|

|

|

| MACHING 2 |

MACHING 3 |

MACHING 4 |

|

|

|

Company Advantage

For more than ten years, our company has specialized in the research and development and production of PCB and FPC electroplating equipment, electric heaters, cold heat exchangers, and coating on the surface of electroplating equipment. We have collected advanced technologies and processes at home and abroad for many years. With the practice and experience in the PCB industry, the quality, stability and reliability of the products are among the world's leading positions. Our company has passed ISO9001: 2008 quality management system certification and CQC: CE certification, is in line with the world, implements scientific management, and implements international quality standards.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!