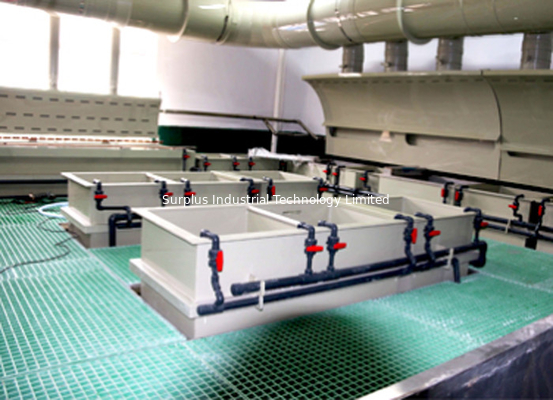

Manual Anodizing Equipment Electroplating Plant Equipment Production Line For Anodizing

Product Description

1. Manual operation, compact placement of the equipment as a whole, small footprint.

2. It is suitable for the experiment of products with small output, self-developed products, and the early-stage proofing of products.

3. The production line is custom-designed in accordance with the technical process and equipment requirements of the anodizing equipment provided by the customer. The entire line design plan follows the design principles of high efficiency, intelligence, environmental protection, energy saving, and stability. Optimize the selection of cloth and auxiliary equipment.

Technology of Anodizing equipment

1. Generally, the surface of aluminum alloy is easy to oxidize. Although the oxide layer has a certain passivation effect, it will still peel off after long-term exposure and lose its protective effect.Therefore, the anodic oxidation equipment production line uses its easy oxidation characteristics to control the production of oxide layers by electrochemical methods to prevent further oxidation of aluminum materials to achieve the purpose of protection and decoration, and at the same time increase the mechanical properties of the surface.In addition, different chemical reactions produce various colors to enhance beauty.

2. The process characteristics of the anodizing production line will produce a hard protective layer on the surface of aluminum parts, which can be widely used in daily kitchen utensils, aluminum curtains of buildings, aluminum doors and windows, medical equipment, mobile phones, computers, computers, sports equipment, aviation components, etc.

Packing & Shipping

In our company,various packing methods are adopted according to different product features,such as carton boxes,wooden case etc.For electroplating plant equipment ,we can discuss it together and choose the most suitable one.

As for shipment,different ways have their own advantage and disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, much more expensive

By Express: more flexiable, door to door, a little bit expensive

Company Advantage

1. Professional,Powerful, Precision Design

- Factory scale: 18 years of experience in electroplating equipment manufacturing, with a production base of 5182 square meters, factory direct sales, reducing customer costs.

- Processing equipment: 20 sets of bending machines, engraving machines, wire cutting machines, processing machine tools and other machinery to ensure the quality of customized equipment.

- Customized production capacity: The annual production capacity of electroplating equipment can reach 24 sets, and the customized equipment can be supplied in a timely manner with strong strength.

2. Build a quality levee to meet the challenges of the century

- Exquisite craftsmanship: simple and flexible operation, stable operation, easy to manage, low mechanical failure rate, high use efficiency

- Superior quality: The equipment adopts materials from well-known brands in Japan, Taiwan and China to ensure stable and durable equipment quality

- Strict quality inspection: repeated testing of equipment after on-site installation to ensure equipment stability and equipment quality

3. Focus on research and development for 18 years, master core technology

- R&D team: Engineers have more than 18 years of experience in the electroplating industry, and continuously improve the quality of equipment to provide technical assurance

- R&D strength: By increasing investment in science and technology, improving the level of R&D, now we have advanced technology R&D and design capabilities in the industry

4. Quality and Thoughtful Service

- The engineer answers online, and the salesman's response time does not exceed 4 hours.

- Quick quote

FAQ

1. How can I get an offer?

You can send your drawing with technology requirements and mark your purchase quantity of the product you need.It is much better if you could offer the usage information about products.

We will comfirm the most suitable material and quote our best price to you in 24 hours.

2. Can you accept OEM & ODM?

Yes,we can produce the products according to your demand and drawing.

3. What is your production lead-time for order?

Generally it takes 15-25 days for production.

4. What are your payment terms?

In generally,we quote EXW price+shipping cost,payment 50% deposit by T/T in advance,50% balance paid before shipment.

If the account is small ,so you can pay via Western Union.

Products Show

1. Automatic Barrel plating production line

2. Automatic rack plating production line

Application: large-scale surface treatment of metal parts such as machinery, automobiles, military industry,electronics and ABS

non-metal parts, suitable for zinc plating, chrome plating, nickel plating, copper plating and other processes.

3. Precision roller

Application range:Small batch surface treatment of metal parts such as precision military electronics, suitable for nickel plating,

gold plating, tin plating, copper plating and other processes

Project display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!